At its heart, digital manufacturing is about using data to attain stability, increase productivity and achieve sustainable manufacturing.

Data can help in surprising ways. It can show you where your processes can be streamlined. It can tell you when a component is near the end of its life. It can even help you understand your people better.

At the AMRC, we can help you harness the power of data to boost your business.

How digital can help your business

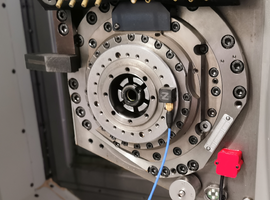

Using sensors, we can capture data from your machines and processes that tell us how they are performing, how much work they’re doing, and when they’ll need changing or repairing.

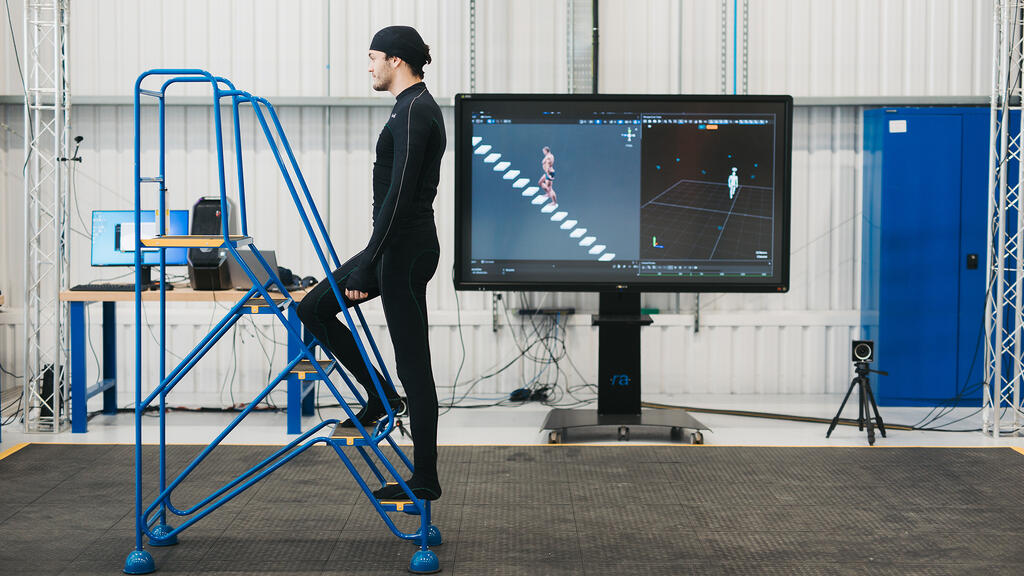

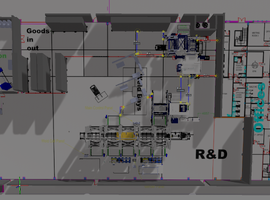

Then we use data engineering and data science to look deeper into your processes to make productivity gains or reduce waste. This goes beyond machines. With human-centred design, we can use data to plan factory spaces that make your staff happier and more productive.

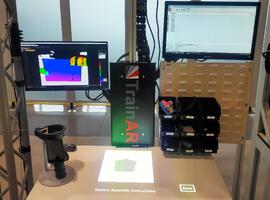

For all this data to be valuable, you need to be able to understand it. We’ll help you bring together data from around your facility, so you can see it all in one accessible place with easy-to-read dashboards, digital twins and augmented instructions.

Talk to usKey capabilities

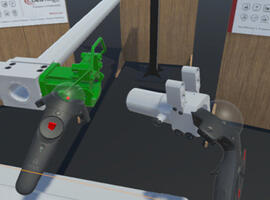

Visualisation is our interface to engineering applications and our research focuses on many aspects including virtual factory management, immersive learning and user experience, applications of digital work instructions and applications of extended reality (extended reality, augmented reality, virtual reality) through visualisation engines.

Understanding data and information across model-based definitions and the adoption across the enterprise enables seamless integration through interopability. We leverage programming expertise to develop bespoke solutions, exploring bespoke automation within business systems and digital threads to empower efficient and optimised data-driven operations.

It enables faster innovation, streamlined supply chains, accurate carbon tracking and eliminates outdated manual systems.

Digital twins are an approach sychronising observable elements to digital representations (ISO 23247) that can be enabled by multiple technologies across the AMRC. They enable better decisions across cyber-physical systems and infrastructures across organisations and wider supply chain ecosystems looking at federated and distributed information to ensure trusted product and process throughout its life.

Information management works alongside the broader digital transformation to enable people to achieve better decisions through technology. Our research is exploring true interopability, data quality, ontologies all to syntactically model and connect data semantics to enable enhanced insights and contextual understanding supported by data standards.

Underpinning the exchange of data between industrial devices and business systems, we specialise in optimising data architectures, while analysing cyber-security measures for industrial networks. Our Industrial Internet of Things research, including 5G and our open-source reference framework Factory+, is enabling: wider data aquision, support of legacy machines, better business wide integration for use cases such as mobile robotics, machine connectivity and part tracking.

How we can help your business

We work with businesses of all sizes and at all stages of their digital journey. You might have a plan and a clear idea of a problem you want us to address. Or you might simply be wondering how new technology can be applied to improve the way you’ve always done things. We can visit your facility or you can come here and see what we offer.

We’ll talk to you about your challenges and either give advice, come up with a solution or introduce you to someone we’re confident will be able to help. We won’t try to sell you things you don’t need, or spend weeks talking about the problem — we’re here to help people with practical solutions.

Talk to us