Connecting smart workbenches to enable efficiency and transferability

The challenge

To examine and develop a systematic approach for facilitating the transfer of work instructions between smart workbenches and connecting them to other intelligent digital tools, to help reduce delays and increase efficiency.

Background

Dylunio Solutions is a design consultancy based in Flintshire, North Wales, specialising in product design and development including small-scale / bridge, in-house manufacturing. By adopting a holistic approach across various industries, the business excels in crafting bespoke products aligned with the unique requirements for each client.

The business was selected for the Accelerating Decarbonisation and Productivity through Technology and Skills (ADAPTS) programme, funded by the UK Shared Prosperity Fund (SPF), which is a central pillar of the UK government’s ambitious levelling up agenda and a significant component of its support for places across the UK. ADAPTS supports Flintshire manufacturers with unparalleled access to advanced manufacturing technology, knowledge transfer, training and upskilling in digital and decarbonisation strategies.

As part of the ADAPTS programme, the team at University of Sheffield AMRC Cymru aimed to provide Dylunio with an efficient solution to share the design manufacturing processes with external manufacturers for approval, reducing significant communication delays.

Innovation

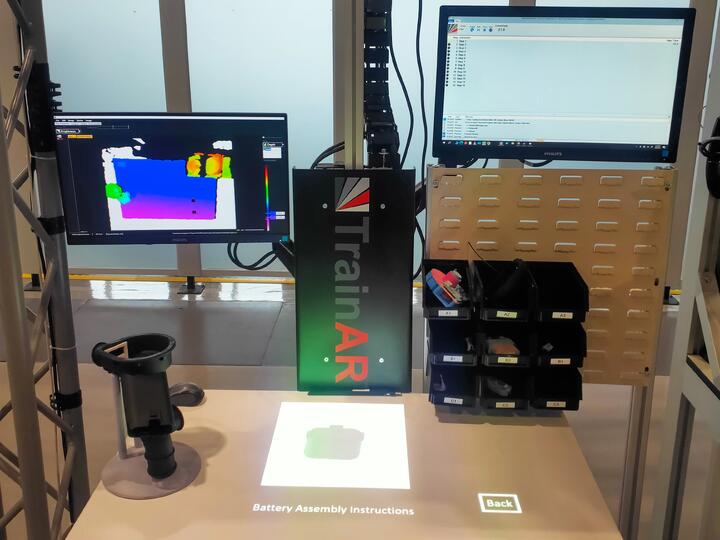

Throughout the project, the AMRC Cymru team utilised a smart workbench to display digital work instructions for a case study product from Dylunio Solutions. The task required the smart workbench to be reconfigured including programming an assembly flow and integrating verification and control features.

The team primarily focused on developing a systematic and methodological approach for facilitating the transfer of work instructions among smart workbenches, and assessing its feasibility.

An additional focus was given to address the challenges associated with integrating a smart workbench with other intelligent tools to further control and trace actions for a particular product assembly. For this, the team examined the methodology for connecting a smart workbench to a smart storage solution to de-risk potential opportunities for the business.

Simultaneously, extensive research was also conducted on smart workbench suppliers to better understand the market.

Results

Using Dylunio Solutions’s product, AMRC Cymru successfully created smart instructions through the diverse functionalities of a smart workbench. The project confirmed the feasibility of transferring assembly instructions from one smart workbench onto another smart workbench of the same brand with minimal setup time.

To enable communication between the smart workbench and smart storage system, or other external systems, it was deduced that the Node-RED tool acted as a fitting intermediary solution without incurring additional costs. Actions between systems were able to be sent using the Transmission Control Protocol.

Extensive research carried out by AMRC Cymru revealed that there were multiple suppliers offering smart workbenches with varying capabilities. This highlighted the market's diversity and the growing interest in using this technology for the manufacturing sector.

Impact

Upon project completion, Dylunio Solutions was able to grasp the fundamental knowledge of smart workbenches, including its benefits through a live demonstration. The project also increased the company’s confidence to invest in a smart solution which would free up engineer’s time to rethink their designs and processes, and potentially mitigate any miscommunication in discussing alterations for a design’s manufacturing process.

The knowledge gained by the business-led to insightful discussions around potentially streamlining auditing processes by exploring the possibility of auditors accessing real-time data on part manufacturing throughout the entire process. This approach could enhance the auditing procedure and build evidence towards using approved smart workbenches for auditing processes, with auditors having seamless access to the data.

The project undertaken as part of the ADAPTS programme also provided Dylunio Solutions an opportunity to increase the business’s potential for job creation in the region through knowledge transfer using Industry 4.0 technologies.