Machining has been a key part of the AMRC since forming more than 20 years ago. In that time, our machining team has worked on huge projects for the biggest names in manufacturing, and helped local SMEs improve their processes and save money.

Now, the drive to net zero and huge technological advances are bringing new challenges, such as, near net condition of supply, new materials and digitalisation. We’re using our world-leading research and expertise to make machining fit for the future.

World leaders in machining

We have an exceptional track record of delivering high-value added manufacturing solutions.

Recently we worked with an aerospace company to manufacture a new type of lightweight landing gear for aeroplanes which uses a new, high-grade titanium material. This will increase the service spans from 12 years to 20 years, with the potential to deliver massive sustainability improvements and efficiencies.

Our work on high-performance disc manufacture with Rolls-Royce led directly to a £30m new factory being established in Washington, Tyne and Wear.

And we worked with Boeing to develop a £40m facility - the only one in Europe - to make gear actuator parts for its 737 and 767 aircraft, creating about 50 jobs and reducing its reliance on external suppliers.

Talk to usKey capabilities

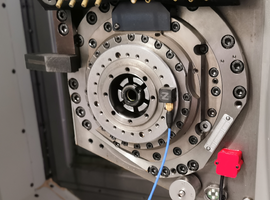

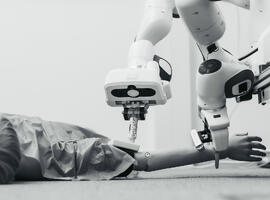

AI and other data science techniques in machining are critical parts of our digital pathway. Coupled with digital twins, these are digital building blocks towards autonomous machining that open up new levels of analyses, helping deliver on two fundamental goals: efficiency and productivity.

We can create digital representations of each element of your machining process. Pairing these with physical data allows you to dive deeper into the details and find those crucial improvements that make all the difference.

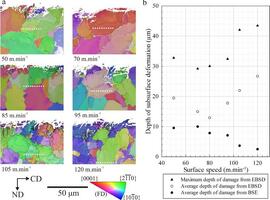

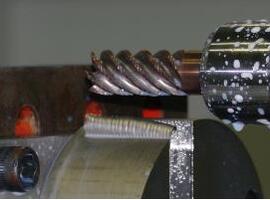

We’re developing machining technology for new materials to prepare for the future needs of UK industry, ensuring that subtractive manufacturing is ready for any disruptions in traditional conditions of supply - for example, near net processes.

Throughout our work in machining, we’re taking the physical into the virtual world. We use simulations to optimise subtractive manufacturing processes against a range of metrics, using less material, saving money, and increasing productivity and sustainability.

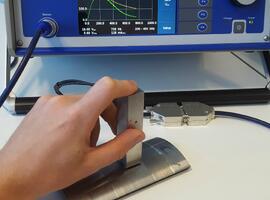

Defects in machining are multi-faceted, with sub-surface integrity being a critical area. We’re researching the replacement of destructive physical tests with non-destructive testing. This will allow us to test changes to processes quickly, using data to speed up the certification and reduce bottlenecks in production. This means less waste, time and cost-saving.

How we can help your business

We have world-leading facilities and a passion for applying the latest research and technology to industry. Our machining staff combines the best of academia, ranging from professors, doctoral and postgraduates to industry-experienced professionals with both technical and managerial experience.

We don’t just work with the biggest names. Every year we run projects with small and medium-sized businesses, from jewellers and watch-makers to major OEMs and the wider supply chain, both here in the UK and internationally, from tooling providers to machine tool builders, and material developers to software companies.

We’re world leading researchers, using the latest predictive modelling technologies to deliver optimum processes. We can offer training across these skills and have a proven track record of successful implementation into our partnership and beyond. Work with us and all of this expertise will be available to you to create long-lasting gains for your company.

Talk to us