Making the ancient art of casting fit for the future of aviation

Challenge

The Aerospace Technology Institute (ATI), which sets the strategy for UK aerospace and funds groundbreaking research and development, identified an opportunity for the UK to become a world leader in aluminium casting.

The casting experts at the University of Sheffield Advanced Manufacturing Research Centre (AMRC) were asked to look at ways to make the centuries-old technique fit for the future, using technology and optimisation to make it a vital part of a more sustainable and efficient aerospace industry.

The project also involved Brunel University and industrial firm Sarginsons.

Background

In 2020, the skies fell silent as Covid grounded planes across the planet. In the UK, the Aerospace Technology Institute approached the AMRC to work within the restrictions of the pandemic to conduct research that could help kickstart the sector after the crisis and be applied as soon as industrial activity restarted.

The team at the AMRC focused on aluminium shape casting. This traditional manufacturing process was increasingly viewed as redundant in the world of 3D printing and next-generation aeroplanes.

The engineers wanted to show that by optimising aluminium casting with technology and more efficient design, they could reduce waste, increase reliability, and improve sustainability — offering big opportunities for the aerospace sector in the UK.

The Foundry 2030 project had three main aims. First, to show that by optimising the design of aeroplane parts it was possible to make them lighter using aluminium casting. Secondly, to demonstrate how introducing automation to the casting process can produce reliable parts that are the same every time. And thirdly, to look at the potential benefits to casting of new digital monitoring techniques.

Innovation

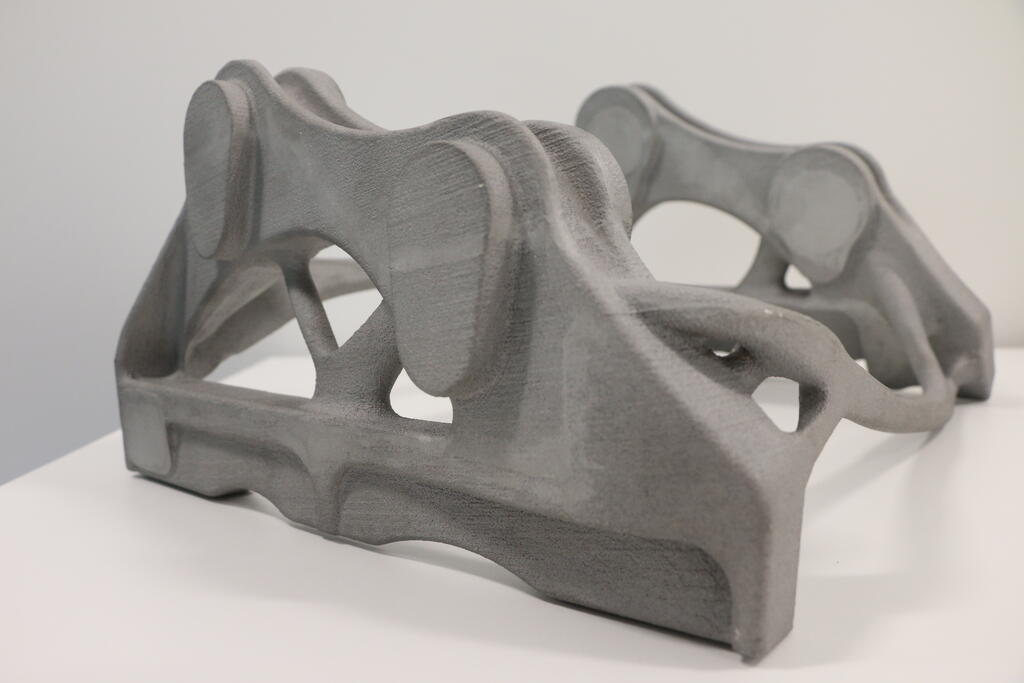

The engineers started with a component from an Airbus A350 aeroplane, which was currently machined from solid aluminium in nine different parts. They used digital technology to optimise different designs for the component that minimised its weight.

They then fed these new designs through casting simulations to create processes for manufacturing the component to ensure the highest quality was achieved. They also ran checks to ensure that the finished product would be strong enough.

Next they needed to prove that their new casting process was repeatable — creating identical parts of the same quality time and again. They conducted ten full melts of each process and found that all the components comfortably matched the specifications required.

They then used the waste material from the original component manufacture to create some more castings, proving that internally recycled material could be used with no detriment to the end result.

Finally, the team conducted a series of tests using digital technology to produce real-time monitoring of the three stages of making an investment mould. This involves coating a material with a slurry, sprinkling it with ceramic particulates known as stucco, then drying the layer and repeating the process with another coat.

Currently this process is tested periodically when offline. The engineers devised ways of measuring the moulds in real time, using technology to monitor weight gains and losses throughout the process. This allowed far greater control over the casting process and fewer costly moulding mistakes.

The image above shows an aluminium casting with optimised topology influenced design of a wing flap roller assembly.

Result

The results of the team’s experiments fulfilled all of its initial aims. The newly-designed aeroplane component and improved casting process resulted in a piece that was less than half the weight of the original one, while just as strong. It reduced the amount of waste material in the form of contaminated swarf from 86 per cent down to 14 per cent.

The AMRC’s new counter gravity casting process produced repeatable components meeting all regulatory criteria for industrial production. And its pioneering use of digital monitoring led to a reliable, repeatable result every time.

Impact

This project and its results are available to support anyone in the UK industry, and they have had significant interest. The AMRC is now working with many aerospace companies that feed products into the aircraft platforms and technologies supplied by global companies to apply the techniques developed in this project to their production.

Sustainability is a big priority for aerospace, with ambitions to achieve net zero aviation by 2050. This research has shown that aluminium casting can be used to manufacture structural aerospace parts where waste has traditionally been high. This can lead to significant savings and an increased use of recycled materials, making a big difference to creating a truly sustainable manufacturing base in the UK.

As the only casting specialists in the UK’s High Value Manufacturing Catapult national network of research centres, the AMRC continues to lead the way in this kind of research.