In an industry with historically low margins, it can be hard to find the time and money for R&D to explore new ways of working. But as construction changes to meet net zero targets — and more and more construction moves off site — you can’t afford to stand still.

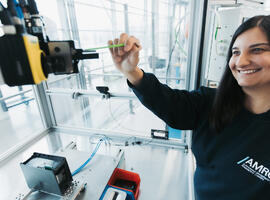

At the AMRC we have a track record of helping the construction sector reduce their costs, increase their sustainability, and boost their productivity.

As part of the University of Sheffield, we can tap into the latest thinking from world-leading civil and structural engineering research. We then use our manufacturing know-how to turn it into practical applications for industry.

Talk to us and we’ll show you how technology meets construction.

How can we help?

We work with companies of all sizes. If you’re a large company in the foundation industries, we can reduce your carbon footprint. If you’re a young startup making hydrogen electrolysers or solar panels, we can research the supply chain to ensure you’re able to meet future demand.

By working with the AMRC, you can benefit from the University of Sheffield’s cutting-edge research in sustainable materials, energy efficiency, and circular economy principles.

We can find innovative ways to enable the scale-up of retrofitting building stock. We can help automate off-site manufacturing, using the latest robot technology to create brick facades. We can research new methods of manufacture, such as additive manufacturing for components, which means buildings can be disassembled and reused at the end of their life.

But these are just some examples.

Above all, we want to know what your challenge is — and we want to use our experience and knowledge to solve it.

Talk to usProject videos

Laing O’Rourke has launched a ‘platform’ approach to design and construction which can be applied to buildings in a range of sectors.

The project was co-funded by UK Research and Innovation (UKRI) as part of the Transforming Construction challenge in conjunction with Converge, Autodesk, ActivePlan, BRE, Hoare Lea, the University of Cambridge, and the AMRC.

The Distributed Automated Cutting System (DACS) project, led by Eurovia UK in partnership with Loop Technology and the University of Sheffield Advanced Manufacturing Research Centre (AMRC), will use a suite of advanced digital technologies to produce bespoke, made-to-measure slabs in a controlled environment, minimising on-site disruption and helping accelerate Britain’s urban regeneration.