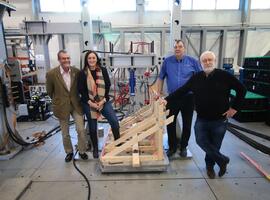

Our UKAS-accredited laboratories test materials and structures to provide an internationally recognised test and validation service. We’re rigorous, robust and independent.

Whether you need to test the performance of a new product, want to understand the properties of a new material, develop a new technology or assess the properties of a new component, we can provide testing support and help you to bring them to market.

Materials, components, assemblies and products destined for various industry sectors including construction, renewables, consumer, automotive and aerospace can be accurately and reliably tested within our facility.

The UKAS accreditation demonstrates that our testing is valid, traceable, objective and undertaken with impartiality, giving confidence that our results can be trusted.

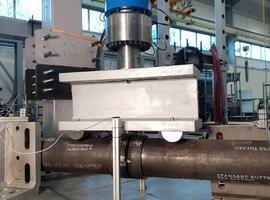

Structural testing

If your product is unusual or innovative, we can design a bespoke testing process and get it accredited for commercial use. From tensile to compression and fatigue to pressure vessels, we provide testing services for businesses of all sizes.

We provide services for businesses of all sizes, from major manufacturers to smaller companies who don’t have their own testing facilities and require independent verification of results to globally recognised standards.

Our flexible scope of accreditation with UKAS, the national accreditation body for the UK, means we can create our own testing methods. This means that if your product is unusual or innovative, we can design a bespoke testing process and get it accredited for commercial use.

We have an extensive range of facilities and systems that are capable of producing up to 2000 kilonewton of force, all backed up by our expert team of engineers who have a wealth of experience in structural testing.

Microscopy

Our UKAS accreditation also covers hardness testing and microstructural examination of metals, alloys and metal products including castings, engine components and forgings.

Talk to us