UK's largest radial braider under construction at the AMRC

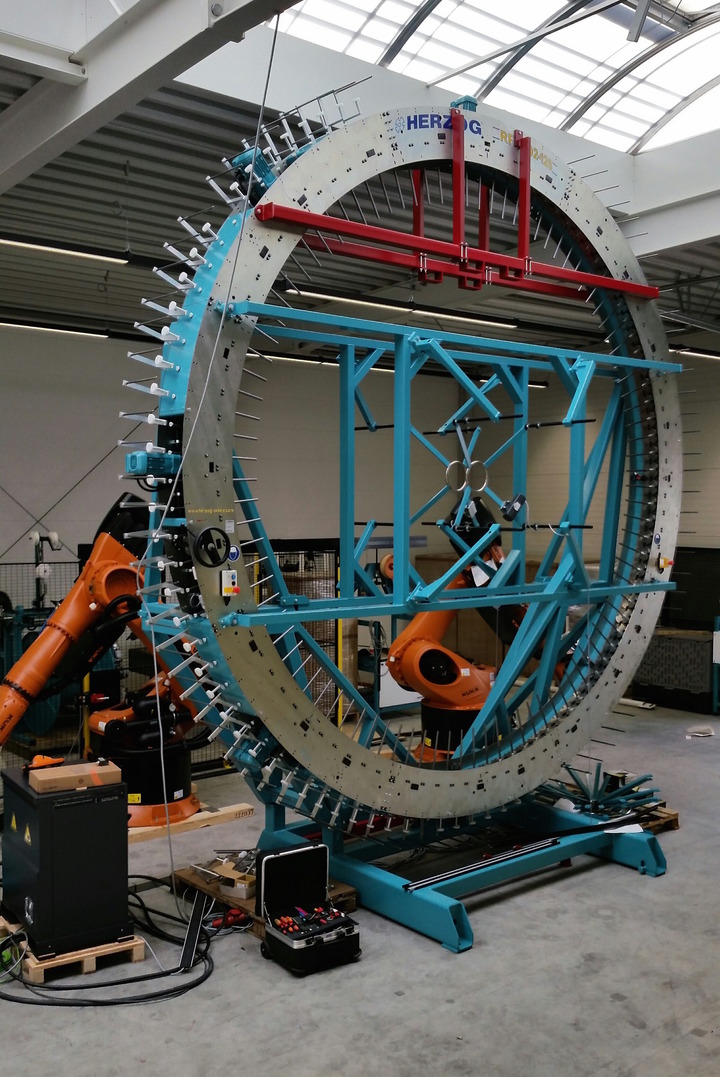

Published:The largest radial triaxial braider in the UK is currently being installed at the University of Sheffield Advanced Manufacturing Research Centre to support the development of complex lightweight preforms for automotive, aerospace and other weight sensitive industries.

The equipment supplied by Herzog GMBH, widely recognised as the global market and technology leader in braiding equipment, is part of a collection of state-of-the-art equipment purchased by the AMRC with funding from the Aerospace Technology Institute (ATI). The equipment will be used to bolster the UK’s position as world leader for advanced composites.

The giant 6m diameter braiding system paves the way for the development of manufacturing complex architectures and features with dry fibre technology, offering the ability to tailor orientations to suit structural requirements as well as allowing both off axis and axial fibres to be laid simultaneously at the deposition rates required for high volume manufacture.

A wide range of materials can be used with the radial braider including carbon, thermoplastic, glass, aramid and co-mingled tows. The Braider is also capable of processing ceramic fibre such as alumina and silicon carbide which would otherwise be difficult to process on a conventional braiding machine.

It has widespread application for components used in aerospace and automotive, helping with the production of fuel pipes and wing spars and numerous car body structure parts. It will also be available to support Dowty Propeller’s multimillion pound Digital Propulsion project to develop future turboprop solutions.

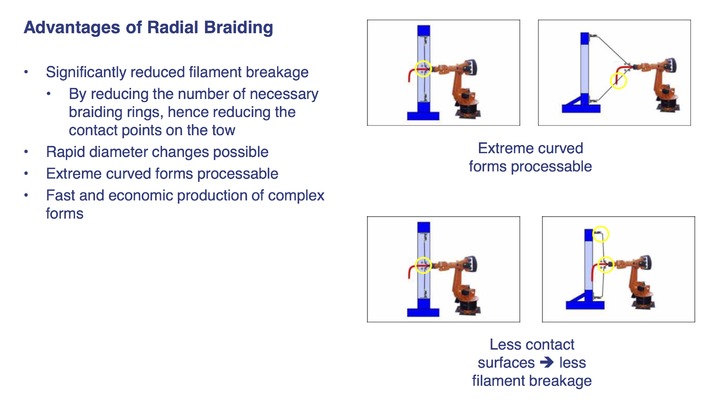

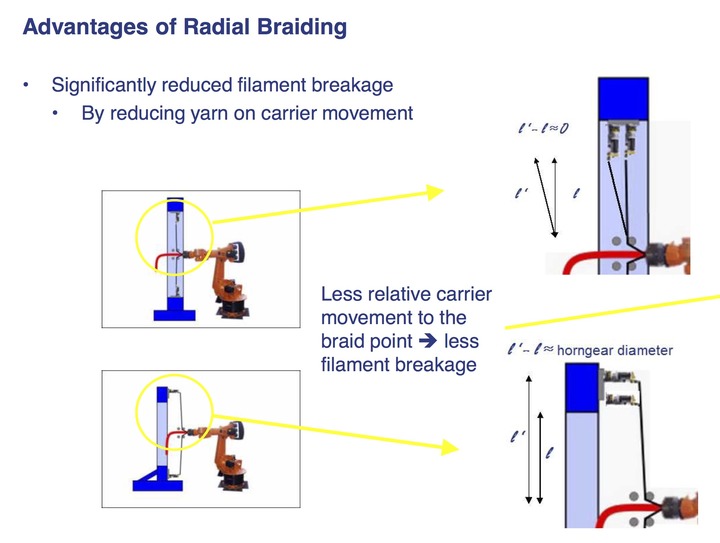

Chris McHugh, Dry Fibre Development Manager at the AMRC Composite Centre, said: “The radial element is a primary feature of the braider as it means less fibre damage and more complex geometry is achievable due to the fact the fibres come down in a flat disc rather than a long cone. The machine is also six-axis with two robots. Quite often one robot is attached to a braider but the AMRC are putting two heavy duty robots either side of the braiding ring. The two 6-axis robots working in tandem means heavy parts and mandrels can be processed and not just foam cores. It is also able to handle more delicate or less stiff cores, due to the additional support.”

The technology, which is open to research projects for AMRC members, external companies and grant funded projects, can be combined with any of the other technologies at the AMRC, including the 1000T Rhodes press and KraussMaffei RTM equipment.

Consultant engineer at the AMRC Composite Centre, Andy Smith, added: “The advantage is it can be combined with other dry fibre technology as AMRC have the full process chain to generate parts to demonstrate industrial scale, high volume production.”

“The AMRC was considering one of these braiding machines over ten years ago when the Composite Centre was starting out, it is technology they have wanted for a long time but it didn’t suit the market at that time, which was focused more on prepeg rather than dry fibre.

“With the setup of this machine, the braider has the potential to process delicate ceramic fibres for metal or ceramic matrix composites which have higher temperature capabilities and higher stiffness - making them suitable for military applications.”

The braider’s arrival follows the delivery of a 3D weaving loom and Jacquard currently under construction at the Composite Centre. Other cutting edge equipment includes through-thickness permeability testing, tailored fibre placement, a high temperature-high tension filament winder, tow-spreading machine and robotic end effectors for automated handling.

It will be used not only to manufacture preforms but also to develop the enabling technology for commercialisation including joining, automation and impregnation.

The AMRC Composite Centre is on the lookout for companies to work with on collaborative research and development projects using the braiding system. Contact Chris McHugh by emailing c.mchugh@amrc.co.uk.