AMRC’s fibre handling expertise helps develop novel prototype

15 May 2023Lower emissions and increased aircraft performance are benefits of a novel prototype machine developed by an industrial consortium that includes the AMRC, designed to improve the coating technology for ceramic matrix composites.

Article featured in the latest issue of the AMRC Journal.

The University of Sheffield Advanced Manufacturing Research Centre (AMRC) has collaborated with Archer Technicoat Limited (ATL), TISICS Metal Composites and Cygnet Texkimp to deliver a project on 'Continuous Interface Coating for Silicon Carbide (SiC) composites’ or CICSiC for short.

The project focused on the manufacture routes for silicon carbide-based Ceramic Matrix Composites (CMCs) - a material of particular interest for high temperature applications of up to 2,000 degrees Celsius in sectors such as aerospace, space and nuclear. The delivery of the project builds on the AMRC’s reputation as one of the leading centres nationally for research in the manufacture of these materials.

The interface between the fibre reinforcement and the matrix is a critical component of CMCs. The project aimed to develop equipment and processing know-how for uniform, continuous coating of interfaces on SiC fibres, such that the mechanical properties of SiC-based CMCs can be more closely specified to enhance their aerospace applications.

This enables the development of more efficient engines, offering significantly lower weight, lower cooling requirements and lower aircraft emissions - resulting in a reduced impact on the environment.

“SiC-based ceramic matrix composites are a promising material for many extreme environment applications including aero engines,” says Ryan Skillett, technical manager at ATL. “The CICSiC project kick-started the development of a new method for manufacturing these high value materials aiming to simultaneously bring down costs whilst improving performance and reliability.”

The project aimed to develop a new reel-to-reel coating technology to replace the current batch coating method to apply interphase coatings to CMCs. In the batch coating method, a preform is made from uncoated fibre which is treated in one step, making it difficult to ensure an even coverage of all areas of the preform with equal precision. The new method uses a reel-to-reel process to apply the interphase coating. Material is wound from its original spool onto a new spool with the interphase being applied in-between. This ensures an uniform coating. As the material is still on a spool, it can easily be used in fibre processing technologies. This allows for shapes with increased complexity to be formed with a uniform interphase coating.

Ryan says the results of the project have drawn international interest from specialists. He added: “The project worked towards the creation of a continuous fibre coating system to work in harmony with the existing batch-based technology, and in doing so, look to take on some of the major barriers to market for the product. The results of this project have drawn international interest from specialists in the material, leading us to believe it has a very bright future.”

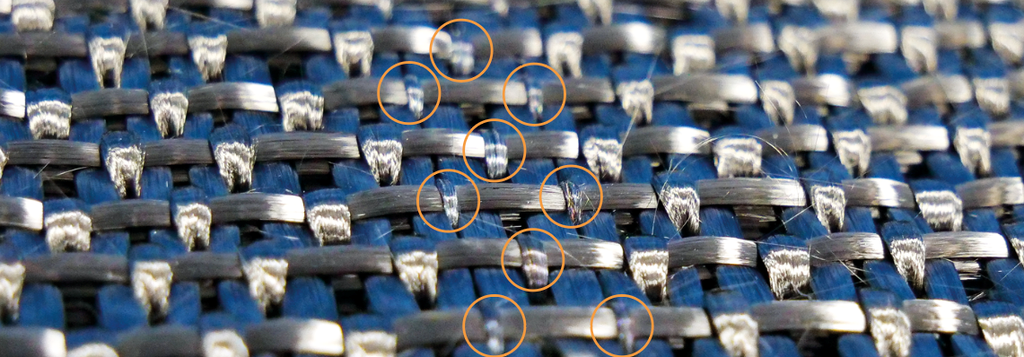

The AMRC’s role in the project focused on the industrial scale processing of SiC fibres to produce preforms with increased complexity. The ability to process the fibre is key to realising the potential of this material. Utilising SiC fibres in processing technologies such as weaving and Tailored Fibre Placement (TFP) is important for building confidence in the handling of these materials so that they can be adopted into industry, and understanding the current processing limits.

The work on handling fibres was performed on as-purchased SiC and on SiC provided by ATL that had undergone the coating procedure in order to understand the difference in processing requirements, limitations and the quality of the output.

“Silicon Carbide composites (SiC-SiC) are of interest to many industry sectors looking at high temperature applications,” said Steffan Lea, a technical fellow in the AMRC’s composites team. “The ability to produce more complex preforms from continuous silicon carbide fibre will enable new designs and applications for this high performance ceramic matrix composite (CMC) material.”

Steffan says the AMRC’s understanding of how to process SiC fibres has developed. He added: "During the CICSiC project, the AMRC has gained familiarity and knowledge on how to process SiC fibre on industrial-scale machines. Our knowledge on how to process SiC fibres on weaving looms to produce 3D woven preforms enables the production of unitised preforms with added complexity. Using the Nicalon on Tailored Fibre Placement (TFP) allows us to make efficient use of the material, only placing it where it is required and controlling the path of the fibre to make best use of its properties.”

Kevin Morris, National Aerospace Technology Exploitation Programme (NATEP) technology manager at Farnborough Aerospace Consortium, said the project has proved to be a ‘very successful’ collaboration, and with the help of funding from NATEP has delivered ‘a winning project’.

He added: “The CICSiC project itself was able to develop the innovation and methods associated with the continuous coating of silicon carbide fibres, and demonstrated how issues could be overcome paving the way for more efficient propulsion systems for future aircraft, fulfilling the aims of the NATEP programme.”

Ryan commended the AMRC’s contribution to the project, adding: “The AMRC provided key insight and experience with handling the fibres, both in their coated and uncoated forms. Without its input, the CICSiC project would not have been as successful and the next generation equipment would not have gained as much interest.”

Andy Whitham, director of process development at Cygnet Texkimp Ltd said: “Working on this project has allowed us to understand the challenges associated with handling very delicate ceramic fibres. These are unusual in some of their characteristics, so having first hand experience of the difficulties involved in their use is invaluable. Beyond that, the opportunity to work with new partners from outside Cygnet Texkimp's main sectors, always provides a different view on the machinery we might supply for a given application.”

The CICSiC project showcases the excellent work done by AMRC’s composites team and the spread of its activities in the SiC- SiC Composites area. It promotes and accelerates the development and manufacture of advanced materials technology and high strength, high temperature materials such as ceramic matrix composites within the UK supply chain.

CICSiC was funded by the National Aerospace Technology Exploitation Programme (NATEP), a £15m programme to develop 60 aerospace technologies in the UK aerospace supply chain. Funded by the Aerospace Technology Institute and managed by ADS, it is aimed at small to medium sized enterprises (SMEs) to develop innovative technologies to enhance their capabilities and increase their ability to win new business.