Building a new future with offsite construction

04 July 2018The Constructing Excellence Offsite Manufacturing and Technology Group witnessed the ‘art of the possible’ for construction manufacturing at a recent visit to the University of Sheffield Advanced Manufacturing Research Centre’s flagship facility, Factory 2050.

The group visited the AMRC as part of an offsite conference day, where members grappled with the big questions and challenges behind the use of pre-manufactured and offsite based systems and delved into the opportunities and benefits around offsite technologies.

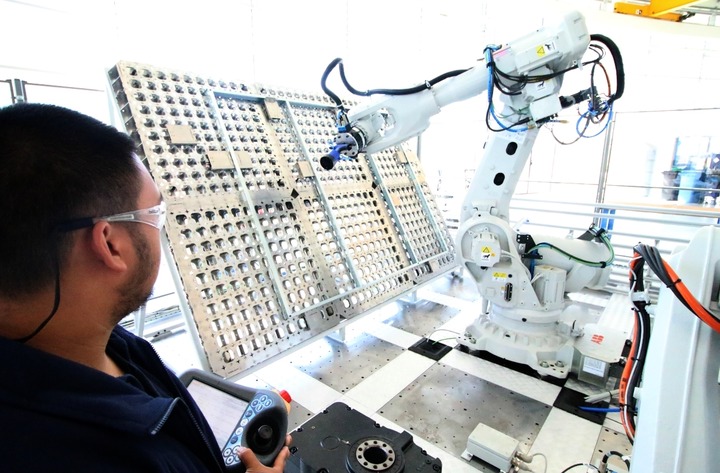

Touring Factory 2050, the group witnessed what is already possible for modular and offsite construction production through a new automated construction project the Integrated Manufacturing Group has installed on its Reconfigurable Factory Demonstrator.

Funded by the High-Value Manufacturing Catapult, the automated construction demonstrator shows how automation can be used to improve productivity and quality within offsite modular construction by automating the assembly of a light gauge steel frame stud wall.

The AMRC’s Head of Construction and Infrastructure Strategy, Allan Griffin also explored with the group the AMRC’s widening interest in the construction industry and how the AMRC is de-risking the innovative technologies that will underpin the industry’s future productivity.

Through exploring innovation and collaboration, the Offsite Manufacturing and Technology Group create a platform for members to effect change and improvement within industry best practice. It consists of members from across the entire construction industry supply chain from clients, to wider industry and end users. Big names such as Heathrow Airport, Tata Steel and Wilmott Dixon were represented on the day, alongside SMEs such as Leeds based Blacc Consulting and Extraspace Solutions from Northern Ireland and attendees from city councils and AMRC members.

Allan said: “Many construction companies are now starting to engage in offsite construction and we wanted to show that by taking a manufacturing approach, they can automate traditional low-value repetitive manual tasks to improve productivity and quality, and in doing so allow valuable skilled labour to be redeployed on more high-value tasks.”

The AMRC showed the visitors how robotic pick and place technologies, coupled with automated tool changes for applying fixings, can completely assemble a stud wall in one operation. When this is incorporated with flexible fixturing, many design variants can be achieved.

“The construction industry has differences in how it has operates compared to other sectors we work with, such as aerospace. Construction companies are typically working with lower margins, therefore investing in new and novel techniques and technology can carry a higher level of financial risk. We are trying to help the construction industry by de-risking new technology that could improve productivity and ultimately increase profitability,” added Allan.

As the construction sector moves more towards a manufactured approach to assets, a lot of the productivity and quality challenges it will face are similar to those that other more productive sectors, such as aerospace or automotive, have already solved. Often there are already mature technology solutions available and the challenge is how to integrate them in a construction context. The AMRC is uniquely placed being at the forefront of aerospace and automotive manufacturing technology development and being able to transfer this technology into the construction industry.

The group also held discussions identifying the direction of innovation, what improvements for the sector are achievable, what parallels can be drawn from the automotive sector and how leadership affects this forward planning for automation.

Companies such as Willmott Dixon, BRE Group and Stackhouse Poland presented to the group on using Building Information Modelling to advance construction projects, the forthcoming BRE Product Standard 7014 (BPS 7014) and linked certification scheme and how insurers see the potential of offsite manufacturing to overcome issues around project delays and quality, as well as improving risk management.

Polypipe Marketing Development Director, Phil Henry attended the conference and said: “It’s great to partner with a construction industry network that is looking at the same challenges in offsite manufacture that Polypipe is and seeing how we can work together with the supply chain to solve them, so Polypipe can continue to bring new products to site whilst meeting the requirements for offsite build.

“Seeing robust business cases for new technologies like the ones we were shown at the AMRC helps companies assess a new technology as a potential challenge or asset and helps companies have confidence in how to improve productivity with a dwindling labour force. The newer technologies have the ability to attract a new younger workforce to what is being seen as a traditional and outdated profession for younger people to go into.”

For Maxine Beadle, Digital for Wilmott Dixon Construction, the conference was a great opportunity to see the advanced technologies being used at the AMRC and how easily they can be adapted for different use-cases: “At the moment in our research and development we are using off the shelf products, so it’s great to see how these technologies can be adapted to suit our design needs as well as looking at our health and safety requirements in some of the industry-ready solutions the AMRC have showcased.

“Everyone has a unique perspective in their specialised areas of construction, so it’s good to gather knowledge on areas we are similarly investigating such as improvements to productivity, safety, training and even how we manage our carbon footprint.”

The conference was also an opportunity for the AMRC to gain valuable insight on the challenges within the construction industry to inform the AMRC’s future development of technologies and manufacturing techniques.

Allan said: “A key driver for the construction industry is productivity. Statistics show that the industry hasn’t made great productivity gains over the last 20 years, so the event was a great chance for us to identify business cases for the use of innovative new technologies that will provide real returns on investment for our partners; something the AMRC already has a global reputation for in the aerospace sector.

“A priority of the work we are doing with the construction industry is to help build up the supply chain, as a high-level of construction work is completed by SMEs,” said Allan, “By exploring and demonstrating the productivity gains that are possible using mature and low cost advanced technologies, the construction industry has a lot to gain.”