2019: The eyes to the north have it

Published:As the New Year and a new decade approach, we take a look back over the year that was 2019, celebrating some of the highlights including the launch of AMRC Cymru, getting the green light for AMRC North West, a talented apprentice reaching the final of the National Apprenticeship Awards, and the University of Sheffield topping the charts for engineering income and investment.

YOU know you’ve got a global brand when the Premier of New South Wales and members of her cabinet travel half way around the world to ask you to be a partner in an ambitious $20 billion project to create a new city and an advanced manufacturing hub for Western Sydney.

All Australian eyes were on Sheffield when Premier Gladys Berejiklian visited Sheffield in the summer. Literally. She had brought with her a troupe of journalists, declaring to Australian TV and press, and the rest of the world, how she wanted to ‘mimic the brilliance’ of the AMRC.

The Premier came to sign a ‘foundation status’ Memorandum of Understanding that would enable the Australian authorities to learn from the AMRC’s experience in using R&D talent and technical skills to transform a region that seemed blighted to post-industrial decline. They wanted to take what they had seen at the AMRC and replicate this back home.

Premier Gladys said: “We want to mimic the brilliance of the AMRC model.

“This is nation-building stuff and I’m so proud that we have been able to secure this relationship to ensure we have the University of Sheffield AMRC really holding our hand through this process; not only ensuring we replicate this success in Western Sydney but actually add to it.”

The new venture has also put the Sheffield City Region on the world stage, with a number of Australian aerospace manufacturers now looking to set up in the region’s rapidly expanding Advanced Manufacturing Innovation District which is creating high-value, high earning jobs for a new generation of home grown engineering talent (more of which later).

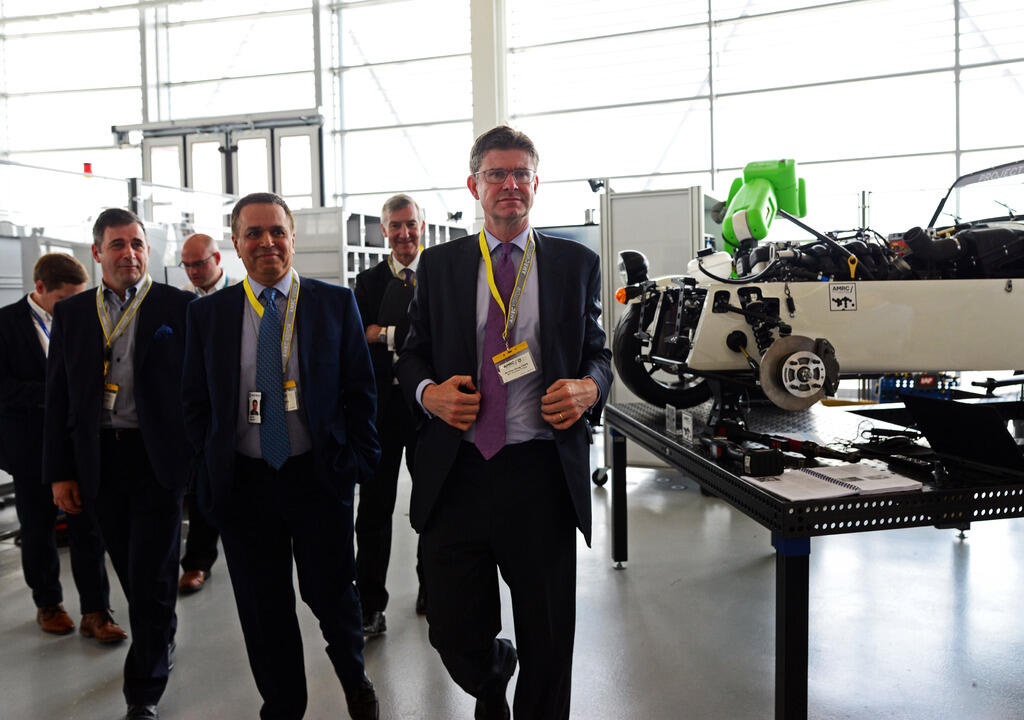

It was very much a balmy summer of love for politicians and the AMRC. A brace of UK government ministers journeyed north over the summer months, curious to see why the AMRC is such a powerful magnet for inward investment for global powerhouses such as Boeing, Rolls-Royce and McLaren Automotive, as well as smaller local employers critical to supply chains, who are using advanced technologies like robotics and virtual reality to develop innovative manufacturing techniques.

Greg Clark, the then Secretary of State, joined University of Sheffield President and Vice Chancellor, Koen Lamberts, to launch the UK’s first, open-access Smart Factory test bed at Factory 2050, paying tribute to the role of the AMRC in providing UK manufacturers with the smart tools they need to improve productivity, win new markets, and exploit-game changing digital technologies to the full.

He told the captains of industry who had gathered to see the £30m boost to the Made Smarter initiative: “It is always a thrill to be here at the AMRC and to see in tangible form the cutting edge of manufacturing that will keep the UK competitive.

“Every time I come here to the AMRC, every time I turn a corner, the pulse quickens when you see just what possibilities there are and how these are creating not just innovations, but real high quality jobs.”

As summer turned to autumn and election fever began to grip the country, the then Minister for Housing Esther McVey met with major developers, small businesses and academics during her visit to the AMRC, where she announced government’s ambition for a new ‘centre of excellence’ for Modern Methods of Construction (MMC) in the north.

She was particularly impressed with the AMRC Training Centre apprentices she met, echoing comments made a few months earlier by Education secretary Gavin Williamson when, after a visit to the AMRC, he highlighted the organisation as a ‘brilliant example’ of how a leading university can collaborate with industry to boost skills and jobs.

Williamson said: “I’ve been hugely impressed by what I have seen here at the University of Sheffield Advanced Manufacturing Research Centre. What they are doing here is a brilliant example of how one of our top universities is collaborating with global firms like Boeing as well as smaller employers to boost skills and jobs across the region. I would like to see more collaborations like this across the country.”

The battle cry from senior ministers came loud, especially from then Cabinet Secretary, David Lidington, who called for more support for the booming research centre following his visit in 2019.

Lidington said had not seen anything quite like the AMRC, hailing it as a good place to convert Britain’s intellectual and research brilliance into practical uses.

He added: “I’ve not seen anything quite like the AMRC. Business and the university collaborating so closely is the key to successful innovation.”

The applause continued when co-founder of the AMRC, Professor Keith Ridgway, took centre stage at the Great Northern Conference with Juergen Maier to spell out their vision for an innovation-led Fourth Industrial Revolution, combining the engineering research talents of the region’s universities with a fast-growing northern skills base being built at places like the AMRC Training Centre.

Ridgway’s message that manufacturing creates value and is fundamental to the success of the UK economy, driving innovation, exports, high quality job creation, growth and productivity is a mantra that was echoed by Lord Sainsbury at the launch of the Centre for Cities’ report, Parks and Innovation, which recognised the AMRC as a ‘nationally significant innovation asset’ whose impact extends well beyond the Sheffield City Region.

Author of the report, Anthony Breach, said: “The AMRC is a locally-based national asset whose benefits are diffused across the entire national economy which means the national government should help support as many advanced manufacturing firms across the country to participate in the R&D outputs produced in Sheffield.”

He noted that the R&D carried out on the Advanced Manufacturing Park benefited not just the local firms and workers but was also ‘exported’ to other parts of country, citing the AMRC’s work with Rolls-Royce in de-risking a £100m investment in its North East fan disc plant securing 300 high valued added jobs, and its ongoing work with Airbus in North Wales to secure the future of wing production in the UK and 6,000 highly skilled, high-value added jobs in the region.

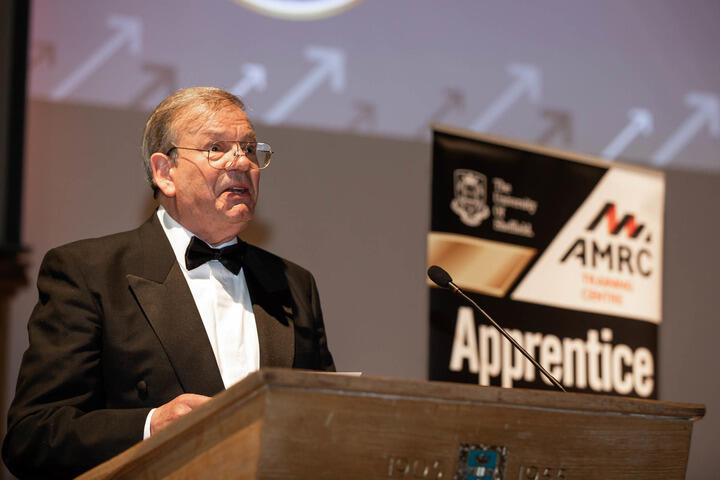

The seismic impact of the AMRC didn’t escape local eyes either. HM the Lord Lieutenant of South Yorkshire, Andrew Coombe, spoke about the powerful, magnetic effect the AMRC has had in attracting inward investment to the area, making special mention of the new McLaren and Boeing facilities whose highly skilled workforces are made up of apprentices from the AMRC Training Centre.

“I think the impact the AMRC has had is seismic. It has been a real beacon of light again for the area and you as apprentices are in the right place at the right time,” he said. “Companies are saying we want to come to Sheffield not just because of the AMRC but because of the AMRC’s training facilities.”

Andrew made the important point that the AMRC is about much more than buildings and high-tech kit: it is all about people. People like apprentice Rebecca Wright, a self-confessed teenage tearaway who turned her life around with an apprenticeship – says she’s proud to have reached the final of the National Apprenticeship Awards 2019.

The 21-year-old works for the AMRC’s Integrated Manufacturing Group (IMG) and won the coveted Yorkshire and Humber apprentice of the year, earning her a place as a finalist in the Royal Navy Award for Advanced Apprentice of the Year at the ceremony in London, competing against other apprentices who triumphed at regional ceremonies in September.

She missed out on being crowned winner at the national final but says being there, and in the top nine advanced apprentices in the country, has only made her more determined to succeed.

“This is my biggest achievement yet. I’ve never felt good enough for any job, especially when it comes down to qualifications and experience. This apprenticeship has made my life and I’m more motivated than ever now,” she said.

“The AMRC and AMRC Training Centre have been a big part in my life so far, they’ve helped me to achieve things that I wouldn’t have dreamed possible three-years-ago. I really do look forward to the many years to come with the AMRC family, I couldn’t ask for more.”

This bright young talent, and the opportunities being opened up to young people across the region by the AMRC Training Centre was championed by Graham Siddall, a Sheffield-raised retired Silicon Valley CEO whose own life was changed by an apprenticeship.

“Without the skill set that my apprenticeship gave me, I doubt that I could have had a more interesting and rewarding career,” said Graham. “I was fortunate to be able to take advantage of the opportunities that were presented to me but I think it's much harder for young people today.

“That’s why it is good to see the University of Sheffield participating in the training and education of apprentices through the AMRC as a complementary path to the more traditional degree courses. The fact that 750 potential candidates applied for 250 places last year at AMRC shows the demand is there from both young people and employers.”

Even top TV architect George Clarke wanted a piece of the action. Clarke said he was blown away by the AMRC Training Centre during a visit to learn about the crucial role the Advanced Manufacturing Research Centre (AMRC) is playing in enabling the construction industry to deploy digital manufacturing technologies for house building.

Clarke came with Mark Farmer, author of Modernise or Die – the government commissioned state-of-the-nation review of the construction sector – to learn about the technologies and processes AMRC researcher engineers are developing for offsite modular manufacturing of homes and schools, and to make construction more efficient and sustainable. At the end of his visit, George said: “This is an incredible place. The level of work that is being done here is amazing.”

Before the year was out, the AMRC extended its reach across the North with the opening of AMRC Cymru in North Wales. The purpose-built research and development facility next door to the Airbus wing-manufacturing plant in Broughton was described by Welsh government ministers as a ‘game changer’ for the economies of Wales and the northern powerhouse.

Wales’ First Minister Mark Drakeford, said: “This is truly a historic day for North Wales. This is a world-class facility which, with its partners, will be a key driver in bringing the latest research, technology and skills to Deeside and the wider region.

“AMRC Cymru will be of benefit for generations to come in North Wales and is part of our aim to have a more prosperous and equal Wales.”

Just a few weeks later, the green light was given to build and equip a £20m state-of-the-art facility in a landmark location at the heart of the Samlesbury Aerospace Enterprise Zone, one of four zones that make up the wider Lancashire Advanced Manufacturing and Energy Cluster, with funding provided through the Lancashire Enterprise Partnership’s Growth Deal.

In addition, a £2.5 million revenue grant from the European Structural Investment Fund (ESIF) matched with £1.6m from the High Value Manufacturing Catapult (HVM Catapult), will secure the creation of a high-performing technical R&D team that will enhance the manufacturing base of Lancashire, working with manufacturing companies and their supply chains.

Chairman of the LEP, Steve Fogg, said: “We have worked hard to attract the AMRC to the Samlesbury Aerospace EZ and backed it with £20m of Lancashire Growth Deal Funding.

“The AMRC will play a key role in helping the county’s aerospace and advanced manufacturing sectors to maintain their leading position in the UK, by driving growth, productivity and innovation and supporting Lancashire firms to compete nationally and internationally.”

The AMRC’s success in securing investment in R&D projects and plant from around the world resulted in perhaps the most momentous achievement achievement of the year: the University of Sheffield was named number the one university in UK for income and investment in engineering research, surpassing Imperial College London, Oxford and Cambridge..

The University attracted £124 million for engineering research from a range of organisations across the world, throughout the UK and from the Sheffield City Region.

Professor Koen Lamberts, President and Vice-Chancellor of the University of Sheffield, said: “This is a monumental achievement for Sheffield. Having a university in the North of England leading in engineering research income and investment is a tremendous boost for the Northern Powerhouse as we seek to boost the aerospace, nuclear and manufacturing sectors and rebalance the UK economy.

“I would like to thank all our staff at our Advanced Manufacturing Research Centre and Faculty of Engineering for the hard work, innovation and creativity that has made this possible."

As 2019 draws to a close, it’s fair to say it has been a busy 12 months for the University of Sheffield Advanced Manufacturing Research Centre, and, looking ahead to 2020, there is no sign of letting up the pace.

So, as we put 2019 to be bed, let us take these wise words from retired AMRC co-founder Prof Keith Ridgway into the coming year: the time for the North is now.