Making virtual a reality for UK manufacturing

19 July 2018Immersive technologies – predicted to be a $160 billion market in the next three years – are fast becoming essential tools for advanced manufacturing, according to a new report launched by the UK’s High Value Manufacturing Catapult at Farnborough today.

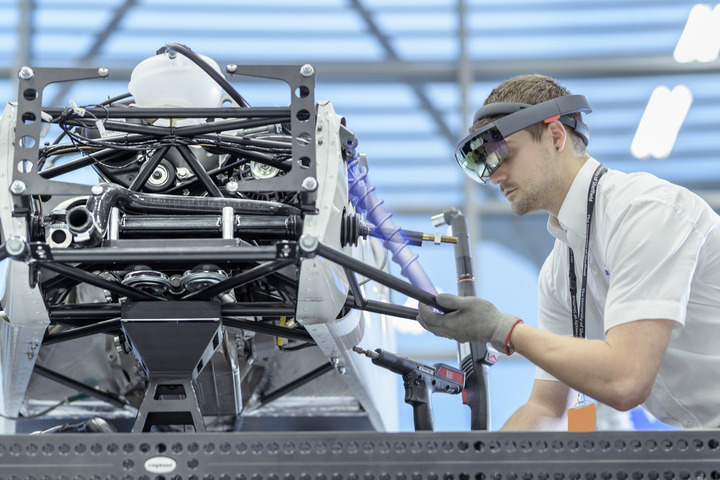

Based on workshops and surveys of manufacturing companies in the UK, the 36-page report urges British firms to become early adopters of immersive technologies such as augmented, virtual and mixed reality, to gain a competitive edge, improve productivity, reduce waste and provide enhanced education and training for the workforce of tomorrow.

“The UK is well-placed to exploit these technologies,” says Dr Sam Turner, CTO of the High Value Manufacturing Catapult, and author of the report’s foreword. “There are more than 1,000 specialist immersive companies operating in the creative and digital market, and what we have discovered is that two-thirds of these companies are keen to exploit other markets, including manufacturing, education, training and energy.”

The Immersive Technologies in Manufacturing report, explores how these immersive tools are currently being used in sectors ranging from aerospace, oil and gas, through to construction, and at all stages through the manufacturing life cycle.

But what makes this report especially valuable, according to one of its principal editors, Chris Freeman, is the way it identifies both the barriers to adopting these technologies and the potential solutions for removing these barriers.

“Our report shows that while there has been a major uptake of these technologies in the last three to five years, coinciding with the increasing availability of low cost, head mounted displays and mobile devices, UK industry risks falling behind its competitors if we don’t maximise the benefits of immersive,” said Freeman, who is Theme Lead for Digital at the University of Sheffield’s Advanced Manufacturing Research Centre (AMRC), and a leading authority on the industrial applications of immersive technologies.

“This report is based on workshops and forums with frontline practitioners. The feedback from this will help policy makers develop the best strategies for removing the barriers to the industrial adoption of immersive technologies, which is a key goal of the Government’s Industrial Strategy and the Made Smarter Review,” he added.

His colleague, and Head of Digital at the AMRC, Professor Rab Scott, said the report identifies leadership and cultural issues as being key blockers to adoption, along with skills, security, time constraints and confusion as to the most appropriate technology.

“The biggest barrier, however, can be finding the justification for the investment in the first place,” Professor Scott added. “We need to be much more active in showing how immersive technologies can influence the bottom line, how easy they are to use, and how relatively low cost their adoption can be. That is where organisations like the AMRC, and the other six centres of the High Value Manufacturing Catapult, have a vital role to play.

“We can give manufacturers hands-on experience and understanding of what immersive can add to their business process and bottom line; we can help them identify the most appropriate technology, support its adaptation for specific use-cases, and de-risk the investment so that it fits seamlessly into their operations,” he added.

“If we get this right, immersive will no longer be seen as a niche activity, or a sort of science fiction process, but as an integral part of business as usual, driving improvements in productivity, design and delivery. This report points us in the right direction, and where better to launch it than at Farnborough, where the most tech-savvy companies on earth are gathering to look at where the industry is now, and where it is going in the future.”

The Immersive Technologies in Manufacturing report can be accessed here.

The report is published by the HVMC Visualisation and Virtual Reality Forum with support from the applied visualisation community. Additional thanks go to Innovate UK, ImmerseUK, the Digital Catapult, and the IET. The principal editors are Devon Allcoat, Chris Freeman, Alex Attridge and Rab Scott with additional input from David Grant, Jonathan Eyre, Andrew Patterson, Alex Smith and David Varela.