Digital manufacturing experts help IT firm boost productivity and reduce waste

18 May 2022A Burnley-based IT business has received a boost in ‘confidence and financial security’ after engineers from AMRC North West used digital support to help transform its work processes and shop floor layout to expand its capabilities and output quality.

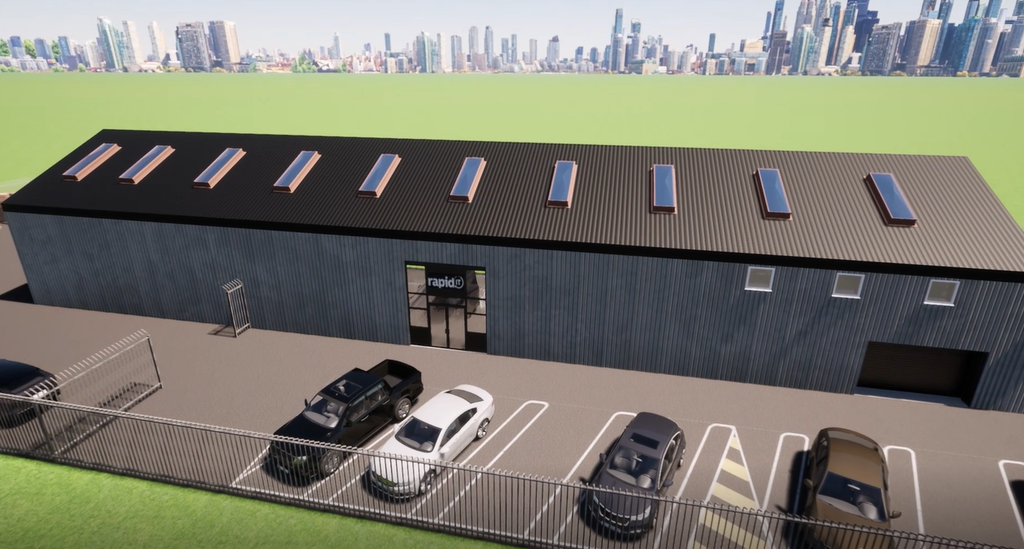

Rapid IT is a fast-growing firm which works within IT asset disposal, data destruction and is a hardware recycling specialist. The company’s growth had been impeded by the space available within its facility and called on the support of AMRC North West to look at ways to increase overall efficiency, reduce waste and increase productivity across its range of services, recycling and production processes.

Victor Giannandrea, non-executive CEO for Rapid IT, said thanks to help from the AMRC North West, which is part of the University of Sheffield Advanced Manufacturing Research Centre (AMRC), the firm is now a more secure business, adding: “There’s a lot of happiness going around the place which we never had before.”

Through its RADAR programme, AMRC North West, based on the Samlesbury Enterprise Zone in Preston, offers a range of fully-funded manufacturing support projects and collaboration opportunities designed to boost competitiveness and productivity for Lancashire’s small and medium-sized enterprise (SME) manufacturing community.

Victor added that the funded project benefitted the business directly after they were able to bring in expert advice to assist with a number of challenges, including process mapping, assessing the factory layout and creating extra space to allow for the additional business they were looking to secure.

“We were helped out immensely in terms of getting us sorted with where we wanted to be,” he said. “It gave us the confidence to go out and look for new business – and from that, we’ve secured two major customers.”

Iain Martin, senior engagement manager at AMRC North West, part of the High Value Manufacturing (HVM) Catapult, said the automation team worked with Rapid IT over the course of two European Regional Development Fund (ERDF) funded projects.

“Our project team helped to analyse and map out Rapid IT’s processes which helped to identify opportunities to smooth out their production flow and increase productivity,” said Iain. “They also produced a comprehensive set of process flow charts, intuitively laid out and can be modified in the future as Rapid IT grows and can help support process improvements and the understanding of key decisions made.

“This solution led onto the second support assist, which involved producing a 2D and 3D model of the premises and a virtual fly through of its workshop, enabling the business to optimise space usage, plan equipment positioning and future equipment acquisition, as well as being able to increase the efficiency of product movement through each process stage.”

Co-founder and managing director of Rapid IT, Jack Banister, said the project proved to be ‘a real eye opener’, adding: “It has made us realise how complex our company is and gave us an opportunity to step back and think in greater detail about our processes and has helped us become more critical of our operations.”

Jack said the company’s biggest improvements since the project had been the increased speed and efficiency in processing assets from receipt at goods in; processing, including data sanitisation, through to resale/recycling, and that these enhancements had created reduced wait times for customers.

“The warehouse design has also been beneficial for our cash flow, as we are now able to process IT assets for resale quicker, enabling a faster turnaround to be able to replenish our funds and we’ve also seen a reduction in our carbon footprint.”

The project was delivered through the University of Sheffield Advanced Manufacturing Research Centre (AMRC) North West’s European Regional Development Fund (ERDF) funded projects.

For further details, contact Pete McOnie, business engagement manager, on 01254 947122 or email: p.mconie@amrc.co.uk