Recycling traceability technology: optimising the packaging circular economy

09 October 2025A three-year partnership between AMRC Cymru and Polytag to develop traceability for manufacturing production lines using cutting-edge digital technologies is a brilliant demonstration of the real-world impact industrial collaborations can deliver for Wales.

Article featured in the latest issue of the AMRC Journal.

Polytag works to provide traceability data to retailers and organisations using plastic packaging of what, and how much, gets recycled.

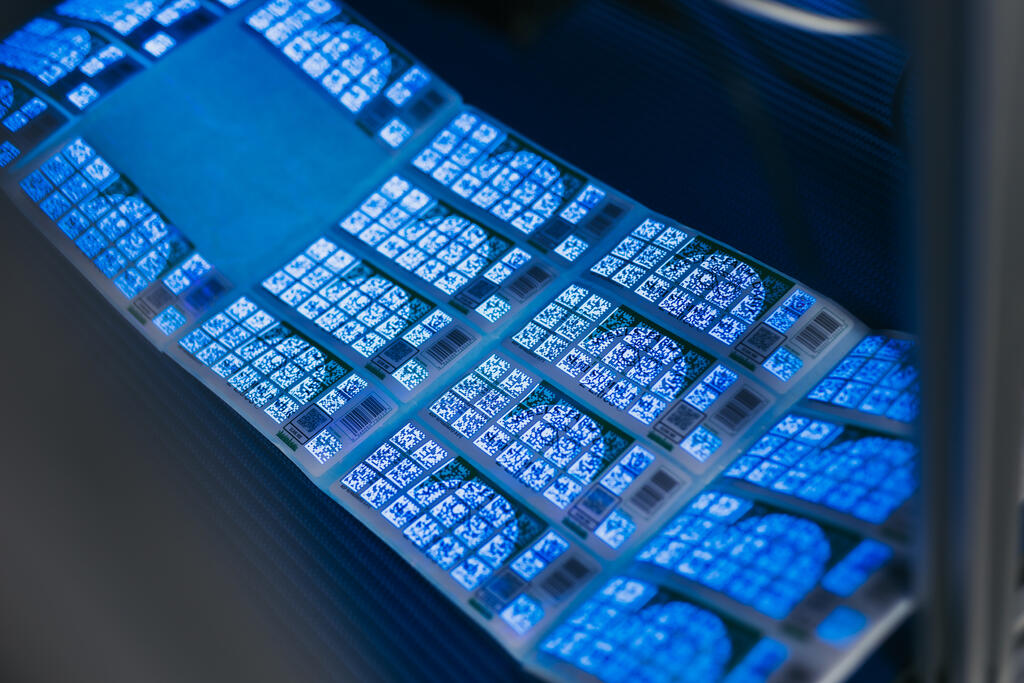

To do this, the company works alongside a wide range of partners across the supply chain and oversees the application of invisible tags onto product labels, using special invisible ink that can only be detected under UV light.

When the packaging, such as milk or drink bottles, get recycled in a waste management facility, the camera on Polytag’s plastic detection units (PDU) detects the product barcode and other data embedded in the tag as it goes through a UV light-only environment, allowing Polytag to report on how much volume of product packaging is recycled.

This, in turn, enables brands and organisations to use that data to make improvements to their packaging to boost recycling rates, and ultimately improve their sustainability credentials, contribute to the circular economy and respond accurately to packaging legislation.

The technology also facilitates the implementation of digital deposit return schemes (DDRSs), a model that Wales has recently become the first country to commit to as part of its broader deposit return scheme (DRS) plans. Additionally, it supports businesses in the upcoming extended producer responsibility (EPR) regulation, providing barcode level data to organisations to help track and prove the correct disposal of and recycling rates of packaging. The technology provides an integrated solution, including an intuitive data-sharing platform, unique packaging identification, and end-to-end supply chain visibility.

For Bobby Manesh, AMRC Cymru’s head of research, the collaboration with Polytag exemplifies the kind of innovative, purpose-driven partnership that the team aim to foster.

He said: "Working together to explore cutting-edge digital technologies for greater traceability and sustainability of single use plastics has not only advanced our shared research goals, but also demonstrated the real-world impact of industrial collaboration in Wales.”

Starting in 2022, AMRC Cymru engineers were tasked with constructing a prototype system to pave the way for Polytag’s technology to take its next step in technological maturity, and optimise its solution.

AMRC investigations looked at how GS1 - a global system of standards - data matrix codes are constructed to meet global standards and then printed, carrying out a broad range of tests to give insight into their ability to withstand various supply chain conditions through the lifecycle of the packaging whilst maintaining their integrity and readability via the Polytag detection hardware.

Printing system development demonstrated the ability to successfully print readable tags, whilst also highlighting improved clarity on a range of packaging substrates, sufficient for proving the concept of UV tagging items of packaging.

Bobby said this early stage of work with Polytag was essential in proving the core principles behind the technology. He added “Developing and testing the prototype gave confidence in the engineering approach and provided a solid platform for further refinement of packaging traceability solutions.”

Cobots and conveyors

Using a simulated material recovery facility (MRF) setting, engineers successfully installed, configured and integrated a robot picker to detect and select tagged packaging by receiving coordinates from a vision system for each item detected, achieving a 100 per cent pick success for detected items. This collaborative robot (cobot) was proven to be successful in acting on the detection of invisible UV tags and can be used alongside humans or as a stand alone solution in recycling centres.

The system developed and demonstrated at the AMRC Cymru facility, from print to pick, indicated that the Polytag aim towards industry adoption was feasible and enabled the Polytag team to continue to develop their vision system solution further through to technology readiness level 9 (TRL9).

Expanding to multiple packaging types

Following this project, AMRC Cymru was asked to test a similar system to the first project, in a real environment, but instead of looking at codes printed on ‘clean’ labels, focusing on codes printed on packaging in a variety of conditions.

AMRC Cymru designed experiments to look at the detection rates of different printing patterns and ink colours, as well as analysing a system developed and commissioned by a third-party integrator. Experiments were run in the recycling facility with ‘clean labels’, and a second run of experiments looked at running the bottles from an earlier stage, seeing how they are detected after being compressed, heat treated or distorted.

The tests carried out provided baseline data on the system as a whole, and also proved that the Polytag system was capable of detecting tagged items under ‘real-world’ supply chain conditions. Additionally, it showed great potential for excellent detection rates for multiple codes, across multiple packaging types within various facilities.

Alice Rackley, chief executive officer (CEO) of Polytag commented: “Collaborating with AMRC Cymru has been transformative for Polytag.

“Their technical expertise and rigorous testing environments have helped us refine and validate our technology, ultimately supporting us to the large-scale industry adoption we have achieved today through work such as The Ecotrace Programme and collaborations with national packaging compliance agencies such as Citeo in France.

“This partnership is proof of what’s possible when innovation meets purposeful collaboration, and we’ve only just begun.

“The insights gained during this partnership to date are laying the groundwork for smarter packaging systems, with the potential to drive change not just in Wales, but across the global recycling and manufacturing sectors.”

Bobby added: “We are proud to support Polytag's mission and look forward to building on this relationship in the future."